Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

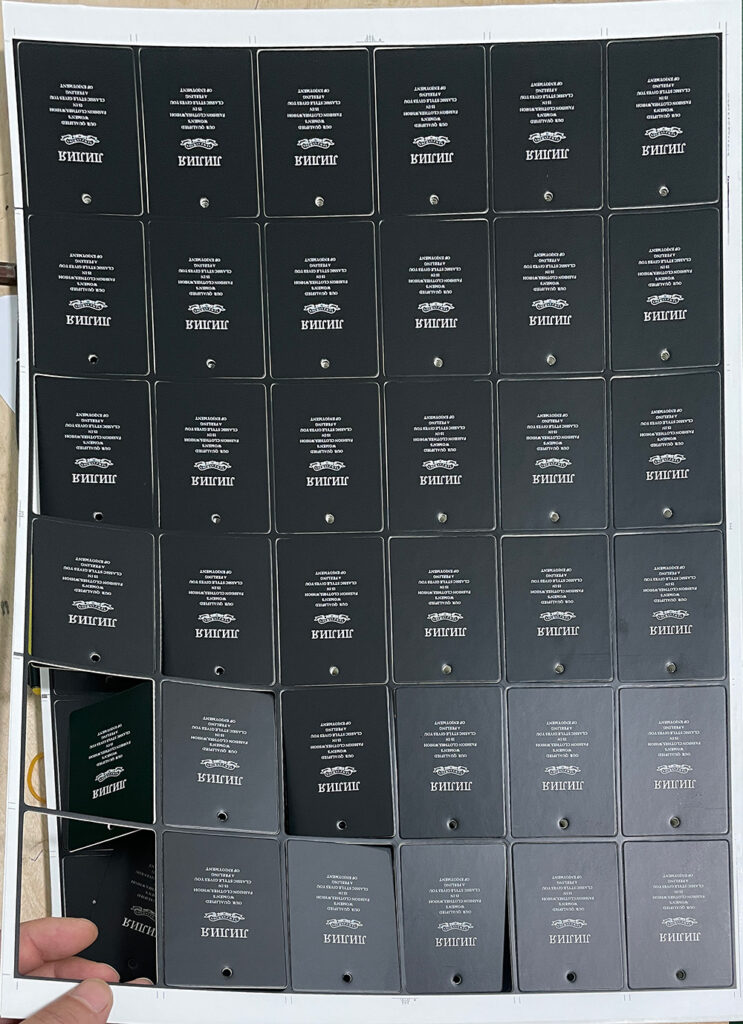

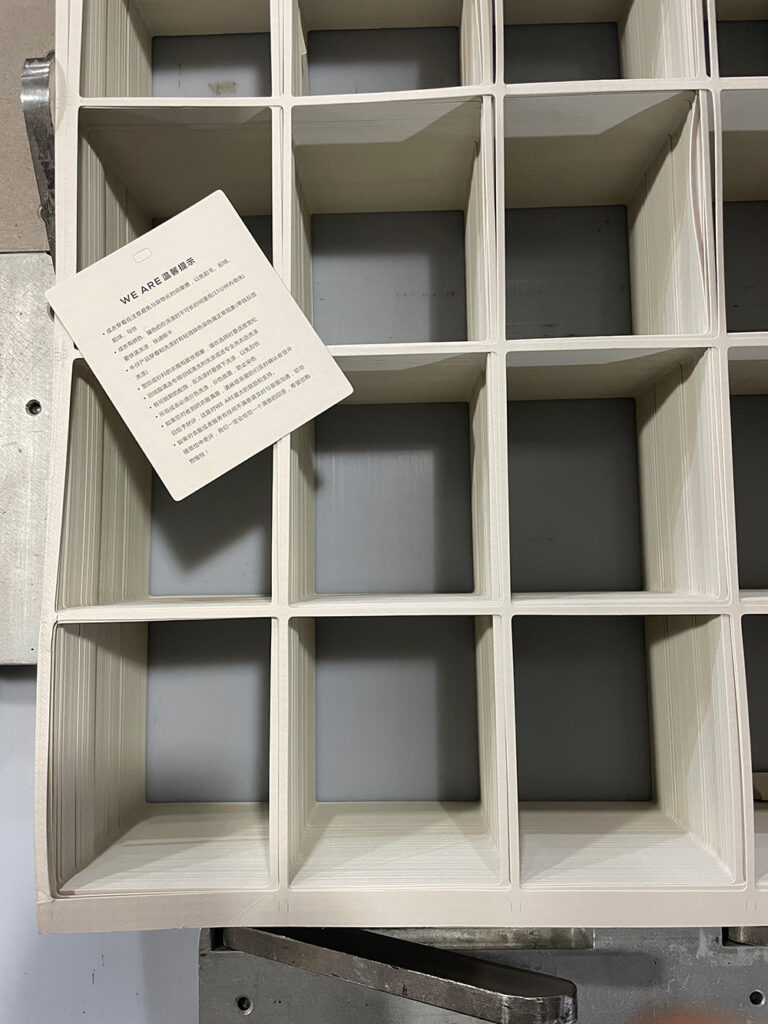

Products such as clothing tags are more likely to fall off during the die-cutting process, which is commonly referred to as loose printing. Because of this, many printing factories still use old-fashioned manual die-cutting machines in the production of hanging tags. In fact, with the technological maturity of the current fully automatic die-cutting machine, choosing a large brand of fully automatic die-cutting machine, such as the customized version of Jiguo MY-800H automatic die-cutting machine, can completely be produced using a fully automatic die-cutting machine. The production efficiency is equivalent to four or five times that of a manual die-cutting machine, and the cost is quickly recovered. The daily production profit is objective.

During the die-cutting process of hanging tags, the customized die-cutting pressure for hanging tags is flatter than that of ordinary die-cutting machines, and the die-cutting pressure balance is high, which can effectively help solve the problem of loose plate during the hanging tag die-cutting process. In addition, it is necessary to be particularly careful and careful in the pressure adjustment aspect, striving to adjust the pressure more evenly and not to apply excessive pressure. When trying to cut the sample with a 70% to 80% penetration of the cutting line, do not increase the pressure anymore. Instead, supplement the pressure in the remaining positions to just the right state through local pressure filling in the impermeable areas.

In addition, the customized die-cutting pressure for hanging tags is more stable than the paper feeding control of ordinary die-cutting machines. This specially designed die-cutting machine has been specially designed and modified in the paper feeding and receiving parts, especially the main transmission mechanism, to minimize the intermittent shaking of the paper in the paper feeding state as much as possible. Only in this way can the paper appear in a transparent and non-scattering state. The convenient paper receiving structure also requires special attention. On the one hand, in order to ensure the orderly paper receiving, it is necessary to adjust the tension and angle of the paper leveling mechanism to make it more conducive to the paper receiving of hanging label products; On the other hand, in order to prevent the paper from scattering during the falling process, attention should also be paid to the adjustment of the tooth opening mechanism, which is similar to the die-cutting state of the puzzle products we have done before.

In fact, the product with a hanging tag is a special type of product, which can only be said to be quite difficult and has special requirements for the machine. However, with proper processing, it is not impossible to achieve this. For printing factories, they should also look to the future and move forward with an attitude of constantly accepting new processes, technologies, and equipment, in order to eliminate competitors, occupy advantages, and achieve faster and better development in the current market environment.