Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Embossed plates are generally divided into two types: engraved plates and corroded plates, with different materials such as steel, zinc, and copper. So how should we choose the appropriate embossed version for different products? You should know that a good embossing plate can achieve twice the result with half the effort when making products for automatic hot embossing die-cutting machines! Because a good embossing plate can achieve both machine saving (the so-called machine saving is to slow down the severe wear of the machine and avoid reducing the lifespan of the machine) and easily create a three-dimensional effect.

Firstly, check whether the grain texture of the product pattern is thicker or finer. If it is thicker, the embossing effect is relatively easy to achieve through machine pressing. There are no special requirements for the selected process and material, but the version should be thicker as much as possible, with a minimum thickness of 3-4 mm or more. The concave and convex texture should be as deep as possible to better achieve the effect. In addition, if the bottom mold is equipped with corresponding resin plates, which are referred to as yin and yang plates or male and female plates, the effect will be better. At this time, it is more common to use a zinc plate corrosion plate, accompanied by corresponding resin plates.

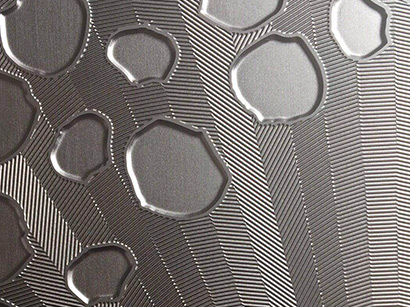

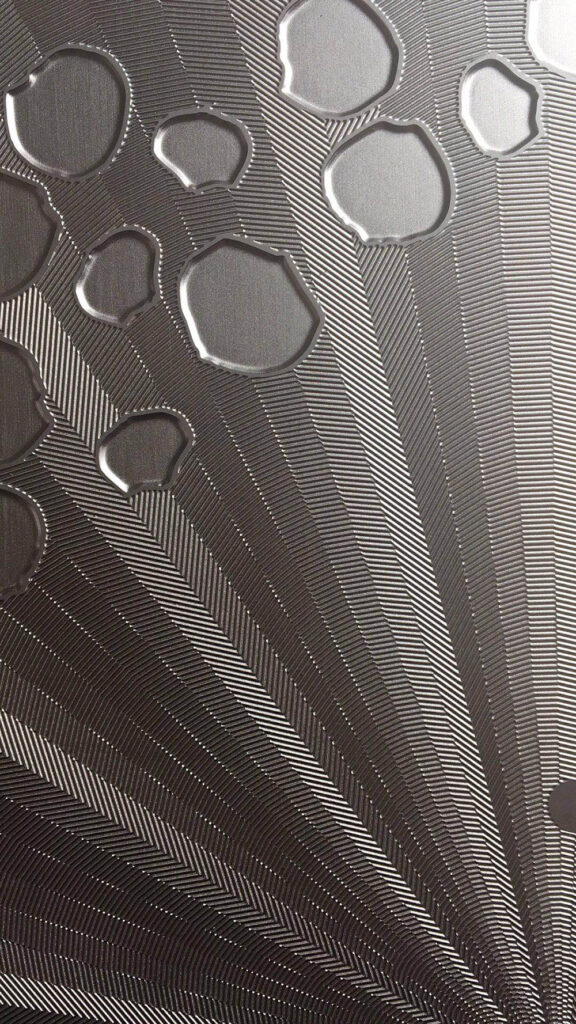

Zinc Plate Example

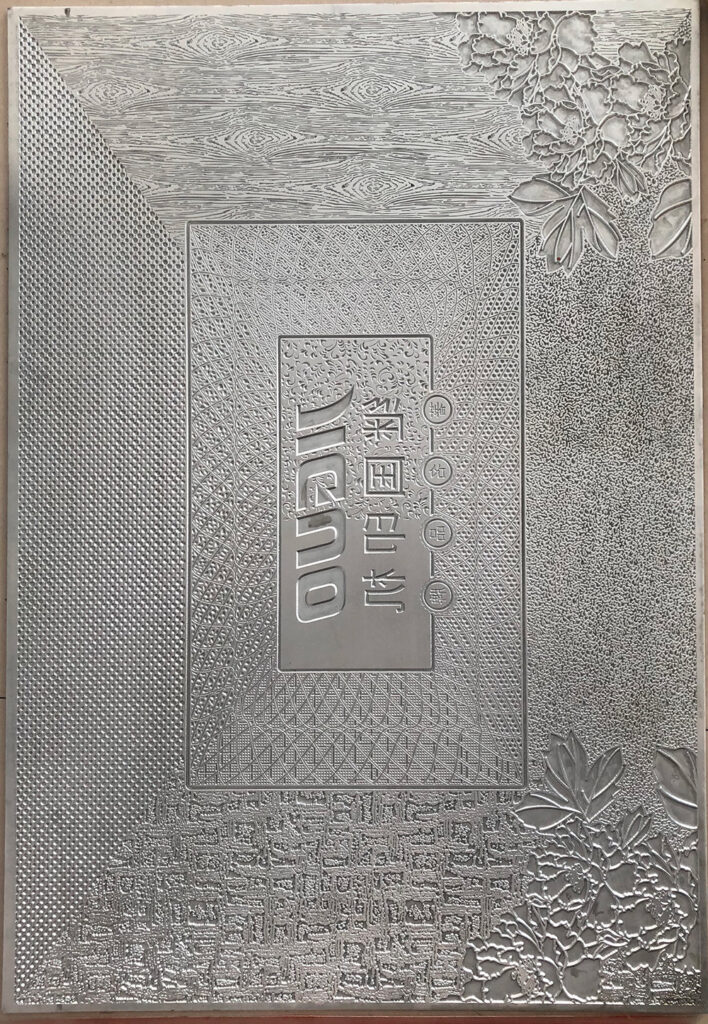

Resin Plate Example

In addition, if the grain texture of the product pattern is too fine, it is difficult to achieve the embossing effect through machine pressing. At this time, the material selected for the embossing plate must be sufficiently hard. It is recommended to choose a steel material instead of a corrosion plate. The thickness of the plate is 2-3mm, and the depth of corrosion exceeds 1mm. If possible, a matching resin plate can be used together. Only with such a matching embossed plate can good results be easily achieved.

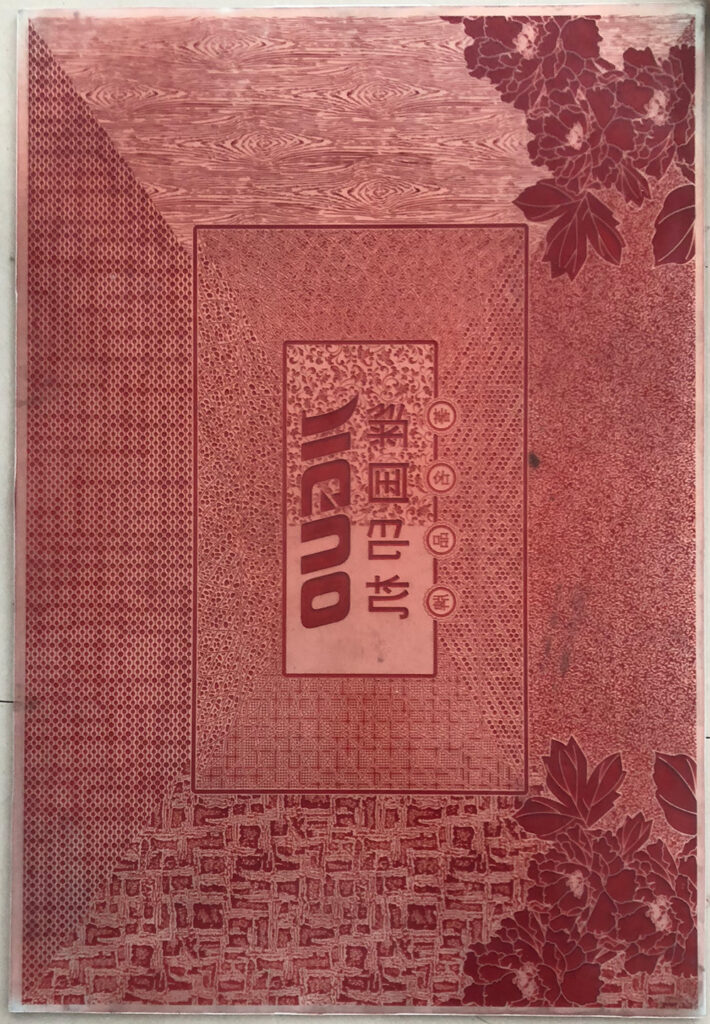

Steel Plate Example

In addition, in terms of machine selection, ordinary pressure die-cutting machines or modified die-cutting machines with heating function embossing machines are not suitable because the working process of hot embossing really requires special machines to provide very high pressure. Ordinary machines may not achieve the effect of hot embossing due to insufficient pressure, and may also achieve the effect but have a short lifespan, Within a few years, the machine will break or be scrapped under high load and pressure. So it is necessary to purchase a professional and specialized high pressure hot embossing die-cutting machine. Recommend fully automatic hot embossing die-cutting machines from the High or Deep series, which are under great pressure from domestic brands.