TMY-880H

Automatic Foil Stamping & Die-cutting Machine

Description

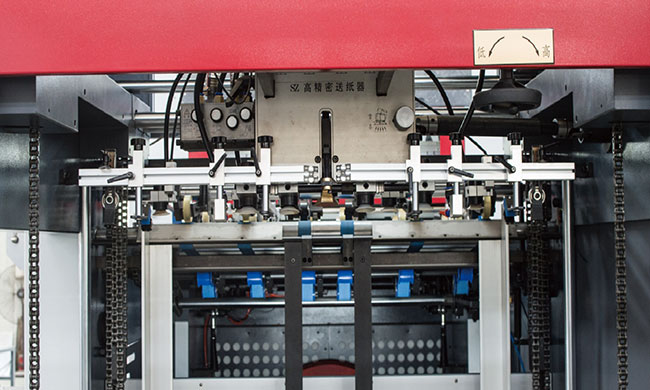

●Improved the strength of the gripper bar, reduced noise, and optimized

the performance of movable and fixed gripper teeth, making it suitable

for different jobs with or without a gripper edge.

●The strength of the side lay has been improved, and the service life of vulnerable parts has been fully extended and guaranteed.

●Enhanced paper feeding speed change mechanism, making paper positioning more accurate, ensuring the processing of thick paper and making it more suitable for thin paper.

●Redesign the die-cut frame with a multifunctional structure that has two locking methods, allowing for easy selection based on the product. The die-cut plate change process is faster, making it more conducive to post press processing users. Lock the die-cut plate with a limit device, making loading and unloading more convenient.

●The front lay adopts an umbrella gear transmission adjustment method, which is conducive to improving the accuracy of the machine and making adjustment more convenient.

●The side positioning adopts bidirectional side positioning of the operating surface and the transmission surface. The operating surface is fixed side positioning, which is suitable for commonly used operating surface side lay. The transmission surface is movable side positioning, using a guide pillar type, which is very beneficial for side accuracy.

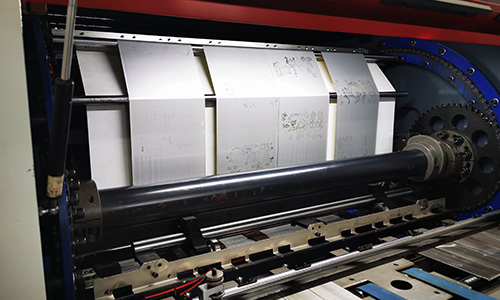

●The stamping system adopts an intelligent temperature control mode, which ensures uniform and fast heating. Constant temperature control can enhance the stability of the stamping effect.

●The fully computerized hot foil stamping structure has foil skip control system which is optimized for servo control, with synchronous foil retraction and release, constant tension, and more accurate.

●The strength of the side lay has been improved, and the service life of vulnerable parts has been fully extended and guaranteed.

●Enhanced paper feeding speed change mechanism, making paper positioning more accurate, ensuring the processing of thick paper and making it more suitable for thin paper.

●Redesign the die-cut frame with a multifunctional structure that has two locking methods, allowing for easy selection based on the product. The die-cut plate change process is faster, making it more conducive to post press processing users. Lock the die-cut plate with a limit device, making loading and unloading more convenient.

●The front lay adopts an umbrella gear transmission adjustment method, which is conducive to improving the accuracy of the machine and making adjustment more convenient.

●The side positioning adopts bidirectional side positioning of the operating surface and the transmission surface. The operating surface is fixed side positioning, which is suitable for commonly used operating surface side lay. The transmission surface is movable side positioning, using a guide pillar type, which is very beneficial for side accuracy.

●The stamping system adopts an intelligent temperature control mode, which ensures uniform and fast heating. Constant temperature control can enhance the stability of the stamping effect.

●The fully computerized hot foil stamping structure has foil skip control system which is optimized for servo control, with synchronous foil retraction and release, constant tension, and more accurate.

Specifications

| Model | TMY-880H |

| Max. Paper Size | 880×610mm |

| Min. Paper Size | 320×240mm |

| Max. Diecutting Size | 860×590mm |

| Max. Stamping Range | 860×590mm |

| Max. Running Speed | 8500s/h |

| Max. Stamping Speed | 6000s/h |

| Max. Feeding Pile Height | 1600mm |

| Max. Delivery Pile Height | 1400mm |

| Sheet Thickness | (Cardboard):0.1-3mm (Corrugated paper):≤4mm |

| Die-Cutting Precision | ±0.1mm |

| Stamping Tempreture | 20~200℃ |

| Heating Plate Zone Number | 10 |

| NO.of Foil Rollers | Vertical 3 and Horizontal 2 |

| Max. Length | 1200~1500m |

| Max. Pressure | 350T |

| Total Weight | 15T |

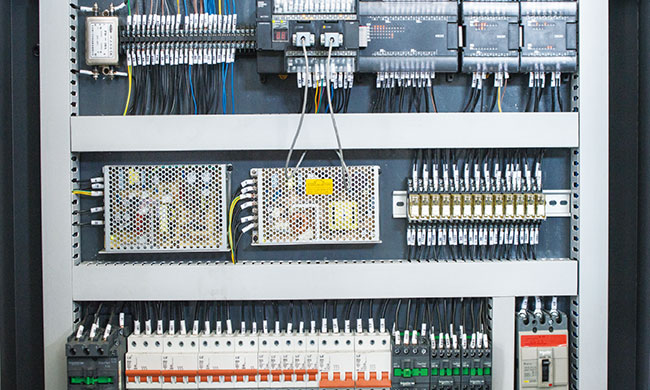

| Heating Plate Zone Power | 28kw |

| Total Power | 56kw |

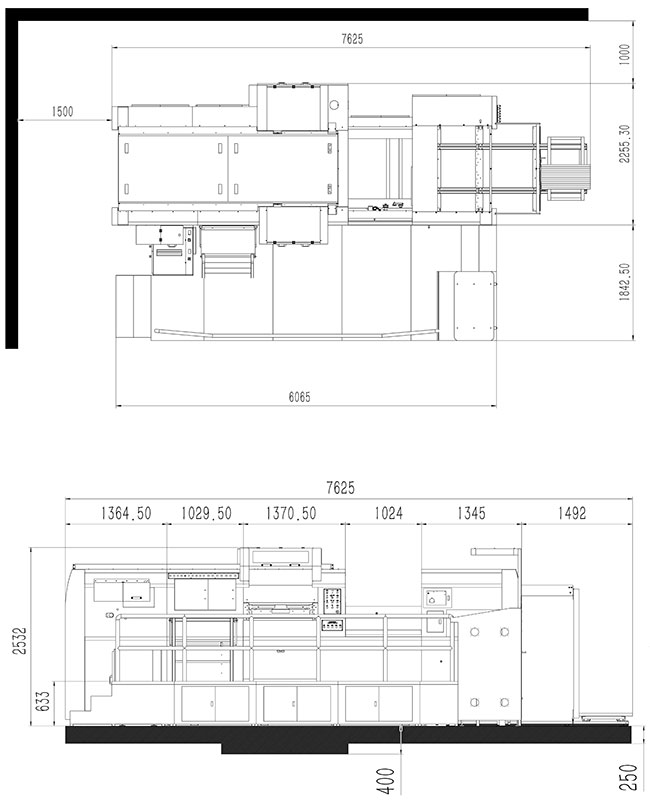

| Overall Dimension | 6800×3950×2300mm |

| Vertical foil stamping section performance specification | |

| Max. foil width | 860mm |

| Min. foil width | 25mm |

| Max. length of pull foil | 590mm |

| Max. pull foil roll diameter | φ200mm |

| Horizontal foil stamping section performance specification | |

| Max. foil width | 590mm |

| Min. foil width | 25mm |

| Max. length of pull foil | 860mm |

| Max. pull foil roll diameter | φ230mm |

| Air Requirements(Buyer provide) | 0.8Mpa,>0.36m³/min |